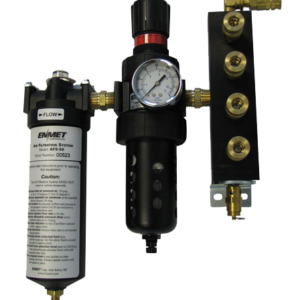

ELM Series

Mist Eliminators are designed to meet the demand for: Efficient removal of oil and mist carryover from piston or oil flooded rotary compressors.

ELM Series (150 scfm – 12000 scfm) High Efficiency Mist Eliminator Air Filters

Applications include

– Capturing oil fog, mist, or smoke from exhaust and pressure

unloading vents on oil flooded compressors, vacuum pumps and blowers

– Any application requiring Low Delta P coalescing of large air volumes

– Vacuum Freeze Drying

– Vacuum Out – Gasing and Vacuum Coating

– Food Processing

– Nailers/Staplers

– Industrial Vacuum Processes

– Cement & Paper Processing

Design

Mist Eliminators are designed to meet the demand for:

– Efficient removal of oil-mist carryover from

piston or oil flooded rotary compressors

– Long service life

– Strength to withstand strenuous operating conditions

– Protection from oil slugs or compressor

Features

– Very Low pressure drop

– Large oil catching efficiency

– Easy field cleaning

– Positive sealing O-rings

– Temperature (continuous) 36°F min. 176° F max.

– Auto Float Drain is Standard

– Multiple drain Style Options Available

– Pressure Rating of 200 psi

– Removal of particles down to 0.01 micron including coalesced liquid water and oil providing a maximum remaining oil aerosol content of 0.01 ppm

– Increased surface area in a given volume allows low velocity separation of ultra fine oil mist

– Elements are grounded to canister minimizing static electricity problems

Mist Eliminator Element

– Ultra low pressure drop reduces energy costs.

– Positive gasket seals eliminate media bypass

– Filter change out differential 2.5 psi

– True Air / Oil Separator

– Long service life